Coater/Developer LITHIUS™ Series

A leading-edge industry standard system continues evolving

The CLEAN TRACK™ LITHIUS™ Series is the latest coater/developer equipped with high-technology succeeding from the CLEAN TRACK™ ACT™ series. The key concepts are extensibility to advanced processes, high throughput, reduced footprint, improved OEE (Overall Equipment Efficiency), and CoO (Cost of Ownership) reduction. As a leading-edge industry standard system, the LITHIUS™ Series’ high reliability and productivity is recognized by worldwide customers, and even today continues to evolve to meet customer needs for leading-edge technologies.

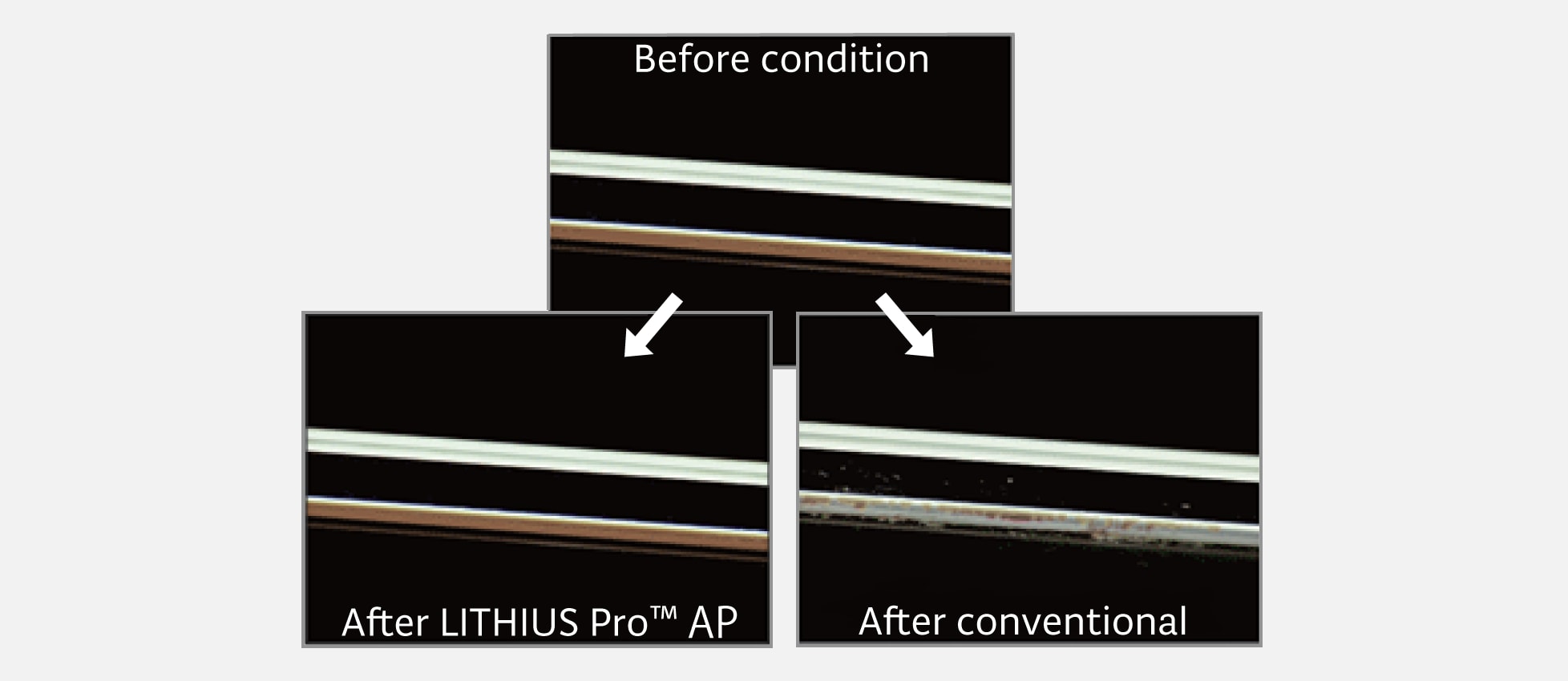

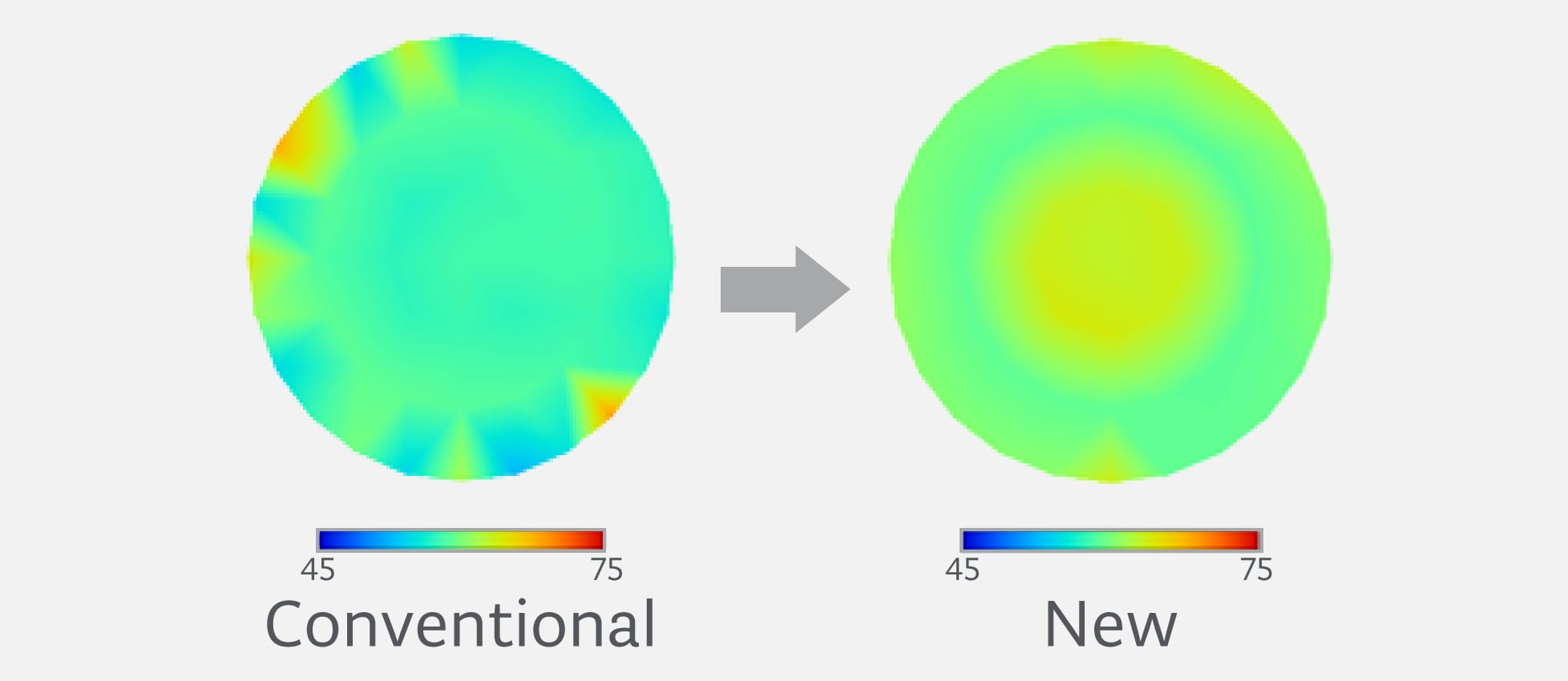

CLEAN TRACK™ LITHIUS Pro™ AP for 300mm wafer processing system incorporates fundamental concepts from the widely-installed CLEAN TRACK™ ACT™ 12, with increased focus on providing optimized hardware and processes to support advanced packaging, high viscosity, and spin-on hard mask applications. Additionally, this platform integrates the latest transfer system with alignment capability and compact spin modules from our leading edge CLEAN TRACK™ LITHIUS Pro™ Z to improve productivity, reliability, and yield. CLEAN TRACK™ LITHIUS Pro™ AP adopts key innovations from our CLEAN TRACK™ series, contributes to improve productivities and yields on advanced packaging and other key semiconductor operations.

Comparison contact area (@BSP)

Coating process for high viscosity material

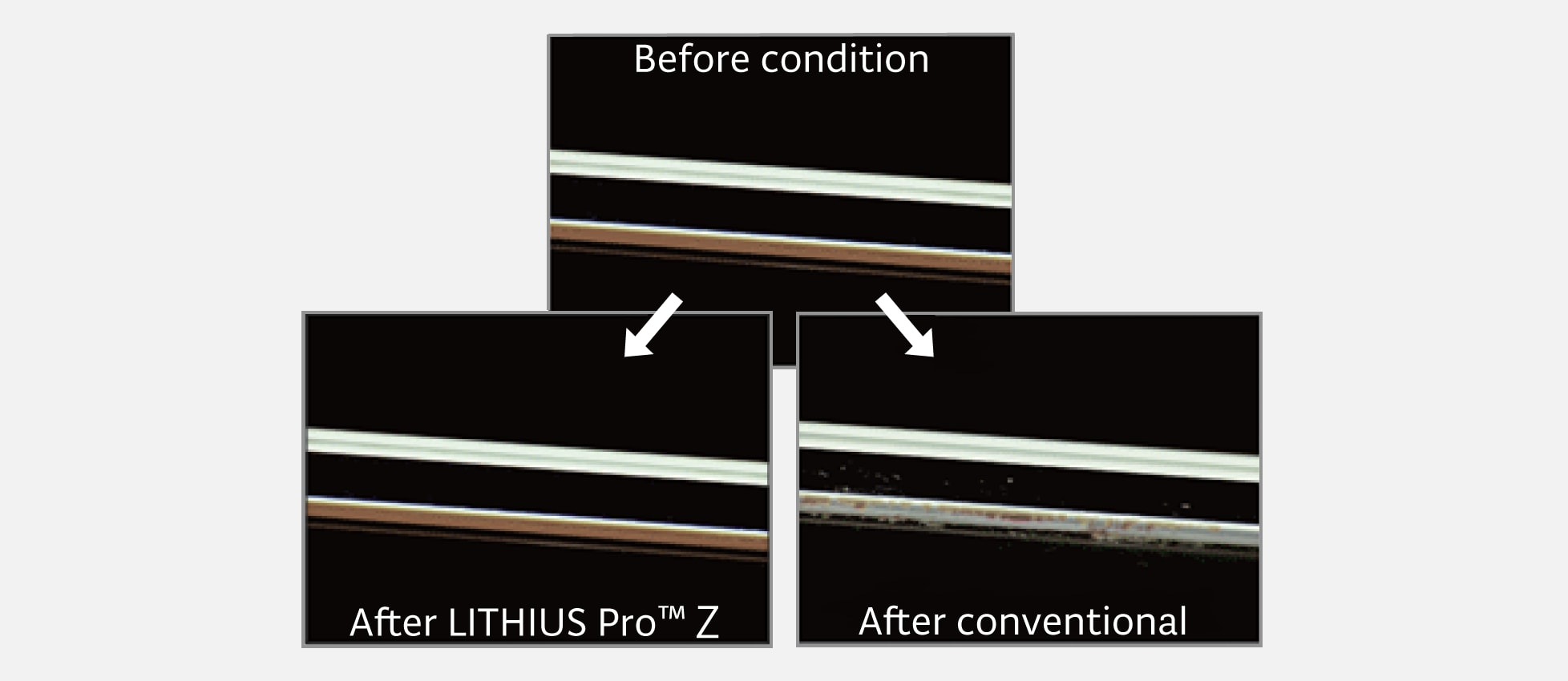

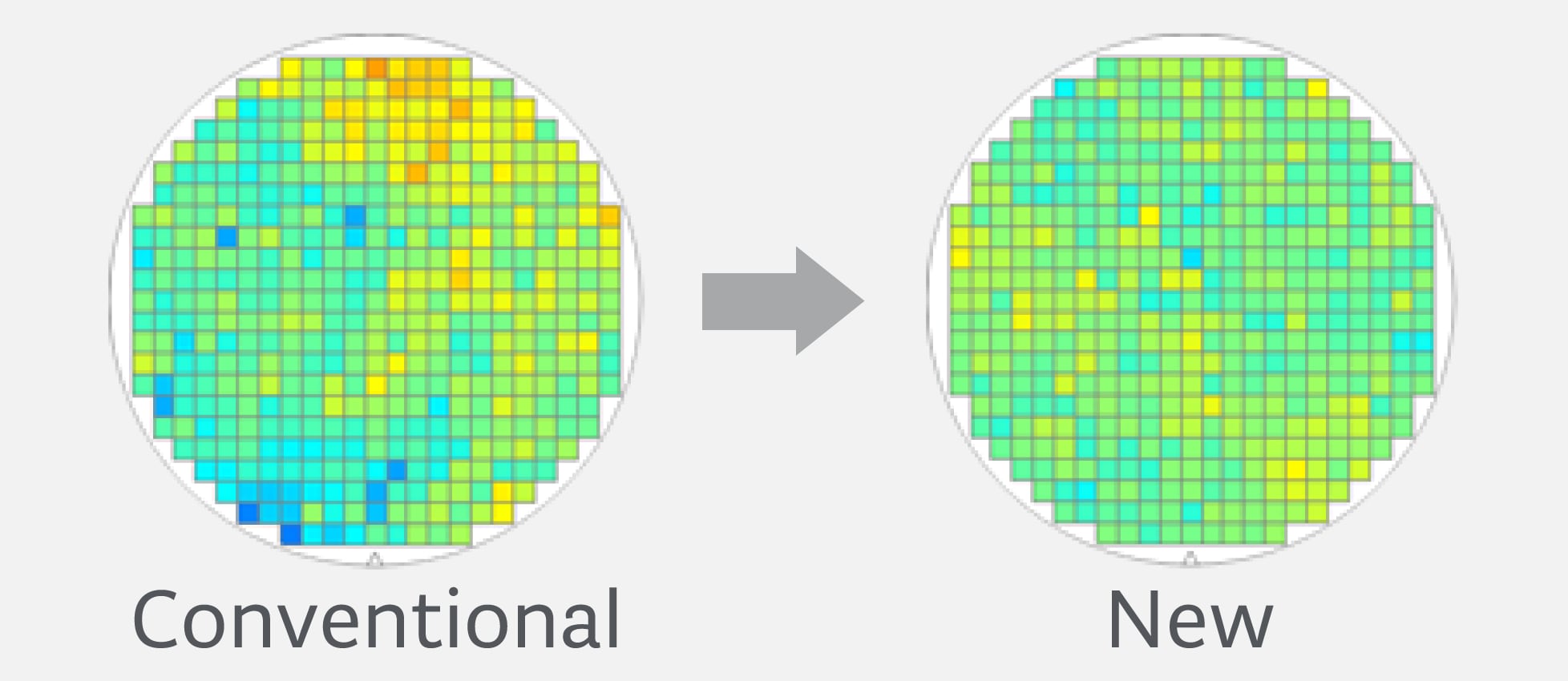

CLEAN TRACK™ LITHIUS Pro™ Z is TEL's most advanced 300mm coater/developer for the 10nm technology node and beyond. It incorporates user-friendly operation, flexible configurations for future processes, and automated monitoring technology to support a wide range of applications from next generation development to high volume mass production. Compared to the previous generation LITHIUS Pro™ and Pro V, the LITHIUS Pro™ Z improves performance in three key areas - defectivity, productivity, and CoO (Cost of Ownership). CLEAN TRACK™ LITHIUS Pro™ Z offers increased process flexibility to support advanced immersion lithography, including double and multiple patterning schemes as well as EUV process.

Comparison contact area (@BSP)

Critical CD uniformity control

CLEAN TRACK™ LITHIUS Pro™ V incorporates all of the advanced technology of the proven CLEAN TRACK™ LITHIUS Pro™ V. It enables higher throughput, increases wafers per day, and improves overall equipment efficiency. Additionally, it also meets industry requirements for versatile lithography equipment capable of leading edge processes, including double patterning.

The CLEAN TRACK™ LITHIUS Pro™ is a 300mm process coater/developer offering enhanced productivity and significantly decreased footprint. It supports advanced immersion lithography through innovative modules and integrated metrology for advanced process control solutions. Additionally, this platform improves upon the core track concepts of OEE (Overall Equipment Efficiency) and lower CoO (Cost of Ownership).

The CLEAN TRACK™ LITHIUS™ is a 300/200mm coater/developer. In response to drastically fluctuating market needs, the CLEAN TRACK™ LITHIUS™ was developed based on three concepts: improved processing, short cycle times, and enhanced network solutions. It achieves increased responsiveness and stability for important process technologies, shorter lead and start-up times, and allows for easier modifications.

Product comparison

|

|

|

|

|

|

| Wafer size (mm) |

300 | 300 | 300 | 200,300 | 200,300 |

| Availability | New | New | New | New | Certified used |

| Throughput (wph) |

200 | Inline: 300 | Inline: 250 | Inline: 200 | Inline: 150 |

| Process | PI, Package, SOD, OCCF, etc. | EUV, Immersion, ArF, KrF, i-line, SOC | Immersion, ArF, KrF, i-line, SOC | Immersion, ArF, KrF, i-line, SOC | Immersion, ArF, KrF, i-line |

| Substrates | Si, Glass, Plastic | Si, Glass | Si, Glass | Si, Glass | Si, Glass |

| Additional features | Flexible configuration for multiple application, High reliability & productivity based on LITHIUS Pro™ Z system | High productivity & process performance, Low particle wafer transfer system, OEE improvement, Reduced cost of chemicals |

High productivity, High throughput with small footprint, OEE improvement, Flexible configuration for double patterning process |

High throughput with small footprint, OEE* improvement, Reduced cost of chemicals |

Metrology integration, Data analysis "Ingenio™", Immersion process capability |

| *OEE: Overall Equipment Efficiency |

CLEAN TRACK,LITHIUS Pro,LITHIUS,CLEAN TRACK ACT,ACT, and Ingenio are registered trademarks or trademarks of Tokyo Electron Limited in Japan and/or other countries.