Identifying material issues

Every year, we look at social issues and business environments, consider risks and opportunities, and examine the opinions and requests of all stakeholders to identify our material issues following discussions and approval at the Corporate Officers Meeting, participated in by the CEO, and a report to the Board of Directors.

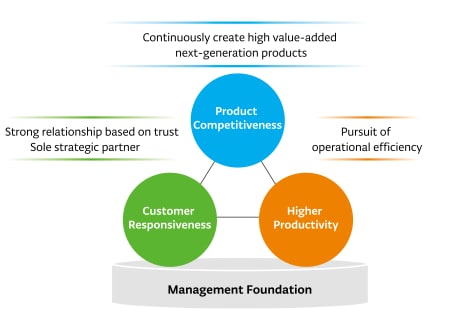

We strengthen our “Product Competitiveness” that continuously creates next-generation products with high added value for the future by pursuing innovative technologies and leveraging our expertise and our “Customer Responsiveness” as their sole strategic partner based on the strong trust of our customers, and engage in "productivity improvement" to continuously pursue management efficiency by improving operational efficiency using digital technology and prioritizing quality in our operations, and enhance our “Management Foundation” including governance, compliance, risk management and human capital in order to support these from a strong financial foundation based on profits.

Process of Identifying Material Issues

| Issues Awareness | Stakeholder Engagement | Identifying Material Issues |

|---|---|---|

Social Issues

|

Shareholders/ Investors

|

|

Wafer Fab Equipment. The semiconductor production process is divided into front-end production, in which circuits are formed on wafers and inspected, and backend production, in which wafers are cut into chips, assembled and inspected again. WFE refers to the production equipment used in front-end production and in wafer-level packaging production. The semiconductor wafer fab equipment includes equipment for wafer level packaging.

Refer toRisk Management

Refer toAnnual Sustainability Goals and Results

Refer to169 Targets of the SDGs

Identified Material Issues

| Material Issues | Awareness as materiality issues | Initiatives to the SDGs |

|---|---|---|

| Product Competitiveness |

|

|

| Customer Responsiveness |

|

|

| Higher Productivity |

|

|

| Management Foundation |

|

|